Recently we have moved our office and workshop to a new location! Konligo can now be found in Circularium, a circular economy centre in Anderlecht, where we will build our tents, pop-up structures and stands from now on. Circularium is 20.000m² of ex-industrial property repurposed for local, social and circular economy organizations in Brussels. At Konligo we are firm proponents for a more sustainable economy, which is why we are very excited to be here. And to make our time here even more agreeable we designed and built our own office ourselves following a circular approach. In this article we will explain how we have applied these sustainable design principles to a mezzanine office and workshop in an industrial hall and what to keep in mind if you want to build with reused materials yourself.

Traditional building design thinking starts with a goal in mind and then makes a design, looking for a supplier for the right materials afterwards. But in order to reduce the ecological footprint we based our design on recuperated building materials, starting with what we had or were able to source sustainably. This does mean that the initial design phase can take longer than usual: you need to think smartly about how to install and connect all the different materials, which often have very different dimensions. In addition, you also have to take into account the dynamic aspect of the life span of an office: one day the building will have to extend or is to be taken apart again, so dismantling or reconfiguration, without demolishing, needs to remain possible. On top of that it’s better to be prepared to put time and effort in iteratively adapting your design. You might start with a great design, but then come across a good deal for some beautiful, recuperated materials which you want to include, or realize that the materials you initially meant to use are no longer available or not of sufficient quality. That will shuffle around your design constantly. In overall, the better prepared you are, the less problems you will encounter when building commences, so the time investment in your design will definitely be worth it.

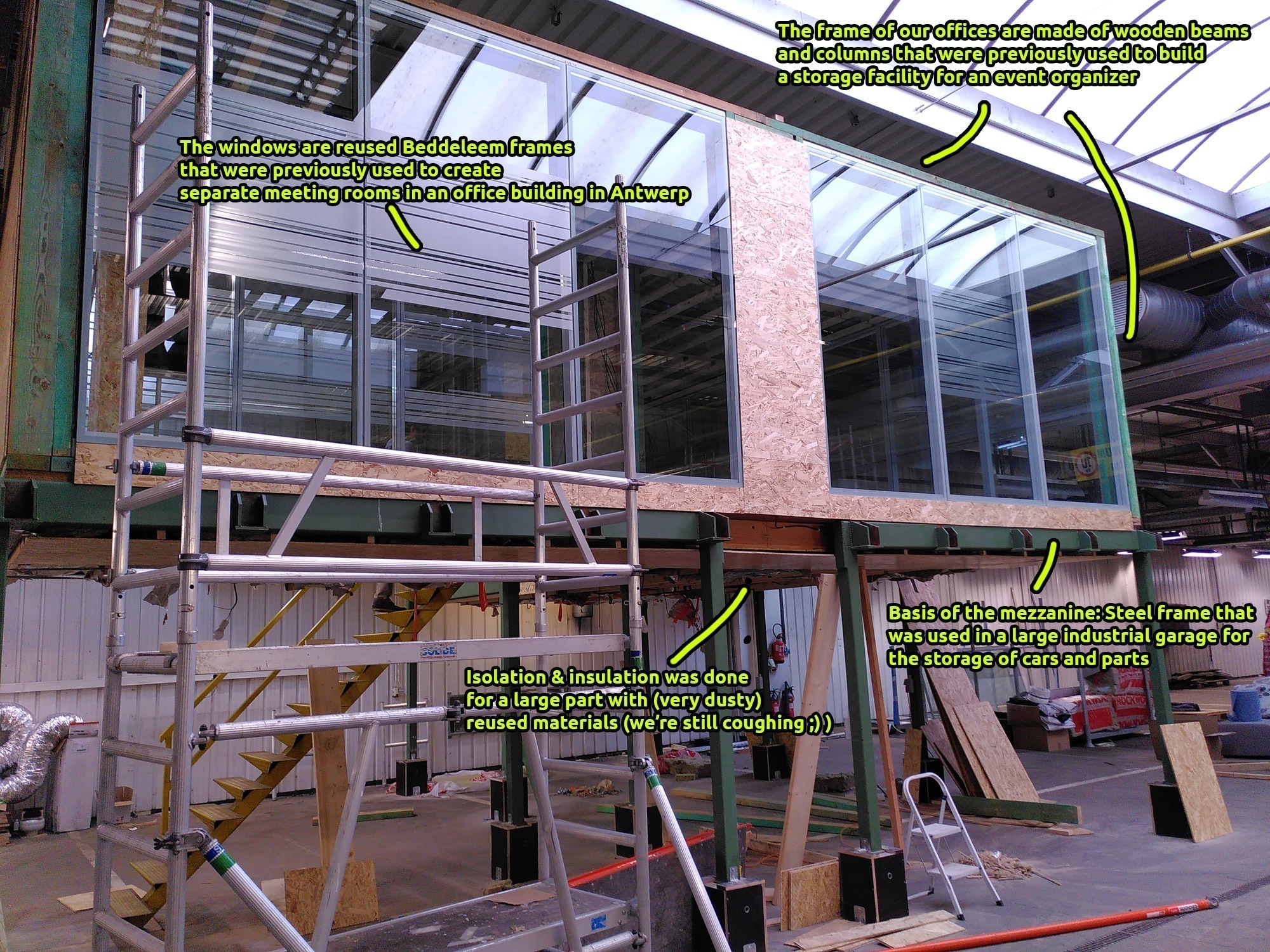

In the picture below, we’ve shown how we combined the reused materials that we mainly bought from BatiTerre and RotorDC. Other items that are not shown like the fence, the carpet tiles and our furniture were found through bankruptcy auctions, or second hand shops.

To keep the design as adaptable as possible, we use only reversible connections (so no welding or gluing, but bolting and screwing) and our carpet tiles are simply lying on the floor and remain in place because they are squeezed in by the walls. Unfortunately, we were not able to find quality reused materials for everything. Our electricity cables and part of the OSB (wooden panels) and wooden beams for the roof are new.

Important to keep in mind when starting your own project is that repurposed and reused materials are not 100% ‘perfect’, as if they have just left the factory. Some wooden beams were bend, some attachments for the windows were damaged, dimensions have larger deviations etc. This does not have to be a problem if you inspect your materials well in advance, and design with the deficiencies in mind. A way to do this is to include more tolerance in your design (don’t go for the millimetre), to measure and remeasure with every building step (to measure is to know) and to be ready to apply some creative problem solving when you find an unexpected problem (but that’s with every project, circular or not =D).

In summary, building a more sustainable office requires a completely different design method than traditional buildings, but the result is worth it! Curious about how we apply circular economy to our pop-up structures, visit our website.